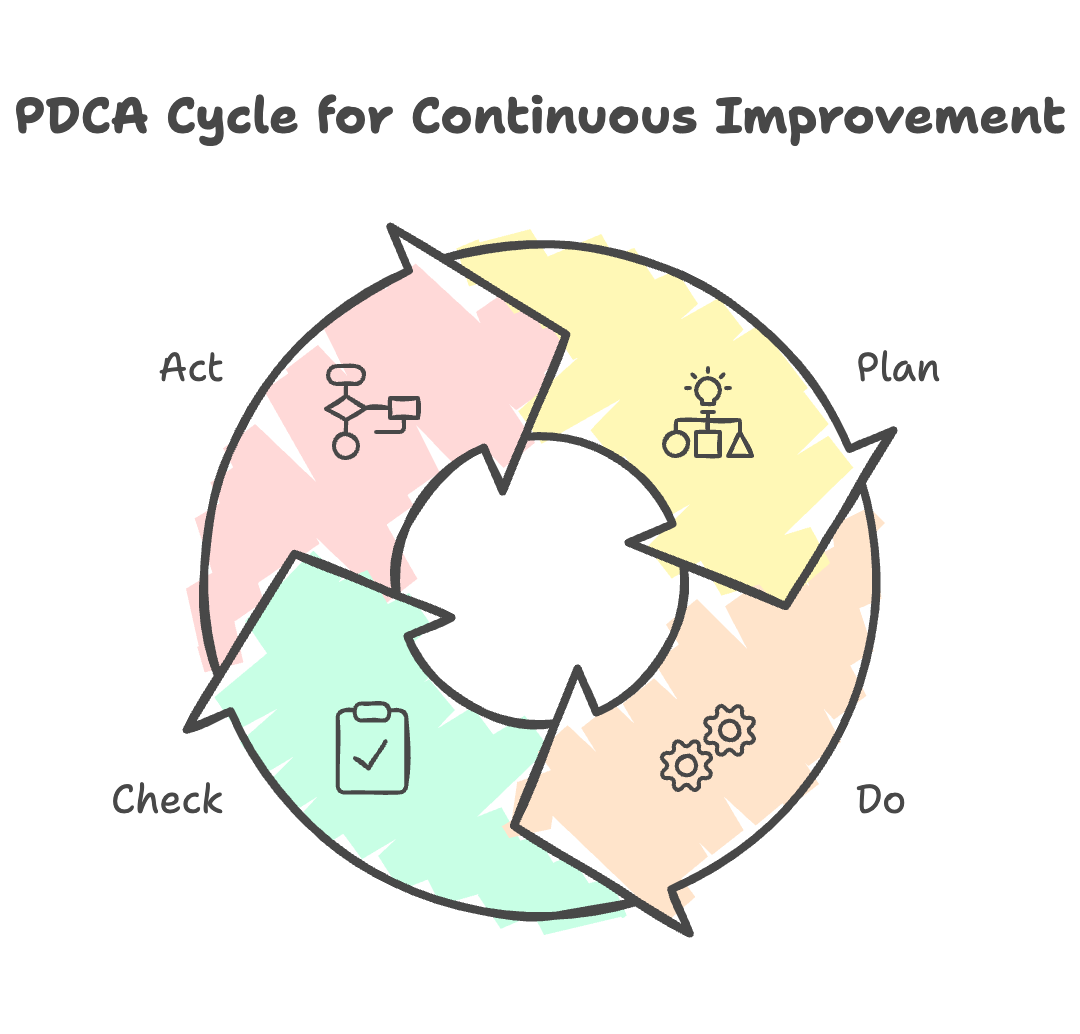

One of the most effective tools for managing change and continuously improving processes is the PDCA method (Plan-Do-Check-Act). This management cycle helps leaders plan actions, test them in practice, evaluate results, and adjust the course if necessary. It’s not just about completing tasks but finding ways to improve them. The PDCA method simplifies and clarifies the manager’s work, enabling them to solve problems and achieve goals more effectively in a world of constant change.

Below, we’ll break down each stage of the PDCA methodology and explain what a leader should do.

Step 1: Plan — Strategize How to Organize Work

Before taking any action, it’s essential to understand what needs improvement and how you can achieve it.

- Identify the problem.

- Gather information.

- Analyze the causes.

- Set a goal.

Example:

A manager notices a decline in team motivation and efficiency. During the planning stage, they investigate the root cause by talking to employees and analyzing productivity data, task completion times, and engagement levels. The manager discovered that the main issues were unclear goals and misunderstandings within the team. They aim to develop a more apparent task-setting system and schedule regular meetings to discuss progress.

Step 2: Do — Implement Changes in Practice

This step involves implementing changes and testing how they work in real life.

- Start small.

- Engage your team.

- Monitor the process.

Example:

The manager begins implementing changes by introducing weekly team meetings to discuss ongoing projects and set short-term goals. They also refine task-setting processes, making tasks more specific and measurable (using the SMART framework). To test the new system, the manager initially applies it to a small team.

Step 3: Check — Evaluate the Results

At this stage, you assess what worked well and what needs improvement.

- Compare results.

- Analyze deviations.

- Gather feedback.

- Document findings.

Example:

The manager evaluates the results a month after introducing regular team meetings and more apparent task-setting processes. They find that task completion times have decreased, and employee engagement has increased. However, feedback from some team members reveals that specific roles are still unclear. The manager conducts additional surveys and conversations to pinpoint the remaining issues.

Step 4: Act — Consolidate Success or Try a New Approach

Now you know what worked and what didn’t. If the results are positive, it’s time to solidify the changes and make them a permanent part of your work process. If they weren’t effective, return to the planning stage and try something new.

- Consolidate successes.

- Learn from mistakes.

- Continuous improvement.

Example:

The manager consolidates successful changes and makes adjustments where needed. Regular meetings and clearer task-setting improved productivity, so they formalized these practices for the entire team. The manager creates additional materials for employees who struggle with task clarity and conducts training sessions. They then begin a new PDCA cycle to improve interdepartmental collaboration and eliminate communication barriers.

In a world where change is the only constant, the PDCA cycle provides leaders with a clear structure for decision-making and continuous improvement. By following its four steps — Plan, Do, Check, and Act — managers can effectively adapt to change, solve problems, and improve their teams’ performance over time.